William Chizhovsky is presently CEO of The Good Plastic Company. The Good Plastic Company is an international manufacturer of surface materials that helps brands to make a visible commitment to sustainability. William and his team’s aspirational goal is to substitute virgin plastic and other non-sustainable materials wherever possible.

We were excited to hear from William about his entrepreneurial journey, which started with small businesses and led to the foundation of The Good Plastic Company. He highlights the importance of combining business success with positive societal and environmental impact. The company's focus on recycling plastic waste for interior design products, its commitment to sustainability, and collaborations with major brands like Nike showcase their dedication to making a meaningful difference in the world.

Alina: Hello, William. I'm sure many of your interviews have started with this question, but it's important for our readers to know how it all began. I'm really inspired by your journey, which feels like something out of an American movie. It's fresh how you openly talk about both your successes and failures, offering an authentic view of your business experiences. Could you please share your story with us?

William: Initially, I had an entrepreneurial background as a founder of small companies many years ago. Later, my studies at Harvard University exposed me to large-scale projects and corporate environments, emphasizing the importance of understanding both small and large business operations. Despite working in a managerial role at a large IT corporation, I always had a plan to start my own business again. During my final year at Harvard, a commencement speech by Mark Zuckerberg left a profound impact. He stressed the significance of achieving success in a field that also makes a positive impact on society, the planet, or future generations. Inspired by this, I aimed to merge scalability and impact, with a focus on building a global business that creates a positive path forward. If you can combine your personal success with something that also can affect not only you, but also on society, the planet, or future generation, then it's win-win. My contemplation led me to explore impact-driven businesses, particularly in response to prevalent discussions about plastic waste and pollution, which remain pressing issues even today.

Alina: How did you come up with the idea of using plastic waste for interior design products, and what was the process like in developing the technology to make it scalable and high-quality?

William: The trend of recycling is widespread, with many people engaging in small-scale initiatives like making bracelets, glasses frames, or T-shirts from recycled plastic. While these efforts are commendable, they often represent just a drop in the ocean compared to the massive problem of 400 million tons of plastic waste each year. To address this issue, we sought to find more impactful applications for plastic waste, particularly in interior and exterior design, furniture, and construction – industries with high plastic consumption.

This idea is new. Before, people didn't think in terms of manufacturing interior design of plastic waste, they didn't think about solving this problem. So that's why we found one very small, very primitive machine on the market, but it didn't work well. It was good for your garage when you want to produce a fair number of very small unique panels. It's funny stuff. It is crafted. But in order to do it on an industrial scale, if you want to collaborate with Nike or McDonald's, you really have to produce high-quality, scalable products. We initially thought that the Netherlands, known as a hub for sustainable development, would be an ideal place to start our business. However, in all honesty, it proved to be a bit more complex than we had anticipated.

So, we adjusted our strategy and created our own team in Ukraine. We spent almost two years developing the technology, and luckily, we have a team of highly skilled individuals based in Ukraine. The team has experience in the construction of plastic recycling machinery. They were serious guys with good expertise. That's why we succeeded with the machinery because now we realize that we might have chosen a wrong direction and then we wouldn't have gotten as good machinery as we have now. But after all the outcome is good, and everything is functioning as intended. And again, when you do something positive, it often feels like the universe is aligning to support your efforts. So that's how it began.

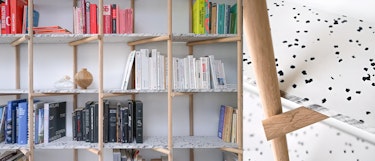

Credit: The Good Plastic Company

Alina: Yeah, Absolutely, trust in your positive ideas and actions can be a powerful force that propels you toward success. When you trust in yourself, the universe is helping you. The mystery is how it works, but it does work. Did you always have a sense that you were destined to be an entrepreneur and achieve something significant in this world?

William: I've always been drawn to new experiences, adventure, and trying things I've never done before. This adventurous spirit is a part of who I am, and I believe it's something many entrepreneurs and innovators share. It's all about taking risks. Some people embrace risk, while others prefer stability in their jobs where they can rely on a regular paycheck and the growth of a secure company. In my case, when I started my business, I took a significant risk by investing most of my family's savings. I knew it was a gamble, but I also had a fallback plan of using my education to secure a job at a large IT corporation if things didn't work out. However, I didn't want to live with the regret of never trying.

Alina: I'd like to inquire further about the benefits which your company offers to customers. You already told me about your technology. Could you share any other benefits that customers can take?

William: Sustainability is becoming a necessity in interior design and architecture materials. We hope our recycled plastic material becomes a standard choice in the future. We aim to create a new category of material where people consider using wood, concrete, or recycled plastic for their projects.

In our case, we offer a wide range of designs and patterns, with over 50 different options in various colors. Designers often choose based on both aesthetics and functionality. We work closely with brands like Coach, Nike, and Adidas to develop unique patterns, giving them the freedom to mix and match colors and forms for a distinct look. In retail design, we offer customization to match brand concepts and colors.

In summary, our focus areas are sustainability, diverse patterns, and the physical qualities of the material. These aspects are not only important for functionality but also serve as engaging marketing and storytelling points, as each recycled plastic piece comes with its own history and origin.

Credit: The Good Plastic Company

Alina: Indeed, there are some unique stories behind your products, and these stories add a distinctive aspect to our work. You mentioned some of the big brands we collaborate with, such as Adidas, Nike, and Coach. Have there been any particularly challenging projects when working with these major brands?

William: Working with large brands wasn't too challenging because they were actively seeking solutions, which we provide. It was a good fit. They were looking for ways to showcase their commitment to sustainability. However, working with retail brands could be more demanding because they often want something new and unique. We'd spend months developing fresh patterns and designs. It becomes an ongoing cycle of R&D and new projects. Retail brands constantly seek novelty, making it a challenge as you're always in an R&D phase.

In contrast, office spaces and hospitality, especially hotel and restaurant chains, prefer stable, consistent products over time. This makes the process a bit easier and more predictable.

Alina: Can you share any notable collaborations with brands or companies that you are particularly proud of, and perhaps highlight a project that was highly desired?

William: Certainly. When it comes to collaborations, I'm particularly proud of our partnership with Nike. They were our first major client and played a significant role in transitioning our material from small orders to large-scale ones. Nike didn't want to just buy a small panel and claim they were doing great things; they committed to using our material in all their flagship stores, purchasing 500 square meters to make a substantial impact. I also have immense gratitude for Nike during this challenging period. When the war broke out in Ukraine, we were in the midst of a significant project for them. We had spent months discussing concepts and patterns, and just as we were about to move forward, the war began. Nike considered canceling the order due to it, but I insisted that we could manage. Despite the war's chaos, we fulfilled our commitment and delivered everything on time. During those initial two weeks of the war, we faced a dire situation as we had recently established a factory near Kyiv. However, we quickly relocated our factory and employees to Chernivtsi near the Romanian border, ensuring their safety and continuity of operations. It was a crucial period, and Nike's understanding and support were invaluable.

Aside from Nike, we've had numerous projects and experiments. One of our early significant projects was a hotel in Delft, the Netherlands, which used our plastic for various applications, including walls and tables. This marked a significant milestone for us in Europe. Despite the challenges we've faced along the way, including war-related disruptions, we've managed to keep our largest factory in Chernivtsi operational, and everything is running smoothly there.

Credit: The Good Plastic Company

Alina: Is there a specific brand or company you've aspired to collaborate with but haven't had the opportunity to work with thus far?

William: We have a strong presence with retail brands, but we're looking to expand into office spaces. Specifically, we're interested in collaborating with companies considering our material for their office environments. As we focus on the U.S. market, particularly California, we're keen to work with tech giants like Google, Amazon, and Apple. We're already involved in various projects with Samsung across different countries. For instance, we're in the specifications for Google's upcoming office in London, which is a substantial and exciting venture. Additionally, we're proud to be specified for a project called Neom in Saudi Arabia. Neom is an extensive city development, and our material is one of the few sustainable options chosen for this remarkable project. It's another compelling endeavor we're part of.

Alina: Could you please elaborate on the primary markets for your sustainable products, and share your insights on how you anticipate these markets evolving in the near future?

William: Our main market is Europe, with the UK and France as the largest segments. We're currently preparing for a significant exhibition at Paris Design Week, our installation focusing on climate change. After Europe, we're increasingly concentrating on the USA, where we already have various projects. Asia, particularly Tokyo, Seoul, and Taiwan, is another area of interest, along with projects in New York and San Francisco. We're also engaged in projects in Africa and have recently established a distributor in the Middle East. While Europe remains a key market, we're shifting more attention to the USA, where sustainability is gaining momentum. We're planning to open a factory there next year to meet growing demand for sustainable materials. We've also received inquiries from Australia, although logistics pose some challenges. Nonetheless, we believe it's just a matter of time before we expand our presence there.

In Ukraine, we're involved in some projects, including charity initiatives like building playgrounds with our materials in previously occupied areas.

Credit: The Good Plastic Company

Alina: And of course, looking ahead, how do you envision the future growth and evolution of The Good Plastic Company?

William: In the past, I used to travel extensively for work due to the nature of my job. I enjoyed visiting major cities like Paris, London, and Dubai, where I could work in central areas and explore stores and public places. Occasionally, I'd come across our materials being used, which was a confirmation of our positive impact. About a year and a half ago, during my visit to Dubai, I inquired at a prominent material library about the use of sustainable materials in architecture and interior design. They mentioned a store named "Make a Difference" in a Dubai mall, where they knew recycled plastic panels were used. To my surprise, these panels were ours. I learned that they were originally from the Netherlands, even though they were labeled as Italian. It turned out that we had sold them to Italy, and Italy had sold them to Dubai. Discovering our panels in a store so far from their origin made me happy, as I had previously only seen them in Europe. That store was the sole one in the region using our material at the time, but now we have expanded. A few months ago, in Chicago, I came across tables made from our material at a large exhibition. When I asked about it, I was told it was part of a British client's showcase.

I am delighted to see our material gaining global recognition and hope for even wider distribution in the future.

Alina: As we wrap up our conversation, I want to emphasize that the trend towards sustainability is indeed a positive and crucial development for our planet. It's one of the most significant steps we can take to ensure a healthier environment. We must contribute something beneficial for the sake of a better world. Thank you very much, William.